SERVICES

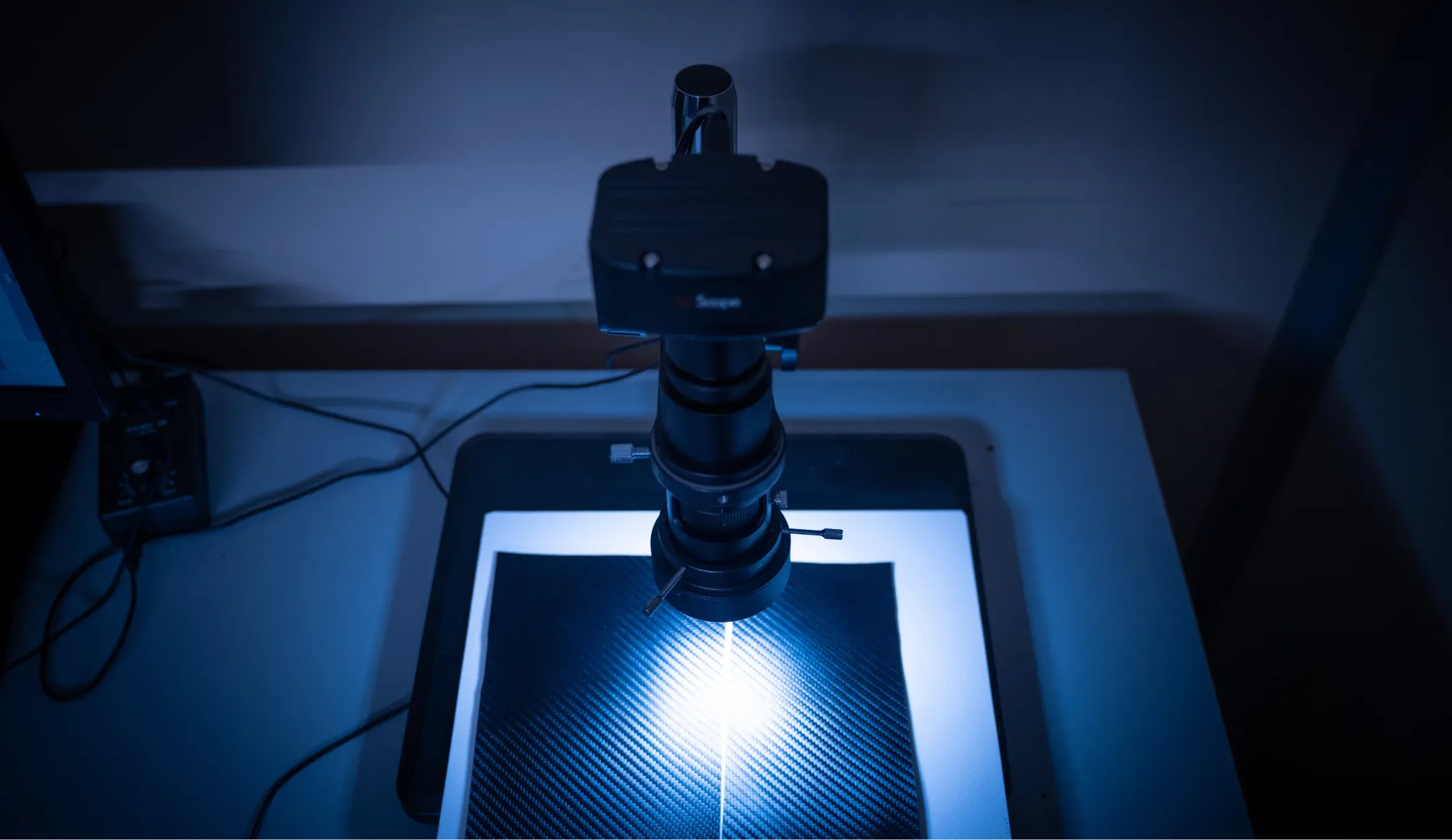

Slitting Kaizen Analysis

"Kaizen" is a Japanese term that means "continuous improvement" and represents a business philosophy focused on processes that continually enhance operations and involve all employees.

With Kaizen analysis, we provide comparative data and verifiable improvements in cutting quality, adjustability, handling, increased tool lifespan, and process reliability using sample blade holders.

Staying on top

With the help of this analysis procedure, we record all factors relevant to an optimal cutting result for your particular application, identify areas of opportunity in your work processes and actively contribute to solving these problems.

DIENES provides you with expert tool selection and optimization of setup parameters to increase the service life of your cutting tools and improve cutting edge quality. In addition, the overall analysis provides information on optimal material usage of blades, measures to reduce set-up times and systems for fast and precise cutting width adjustment.

Approach to analysis

Approach to analysis

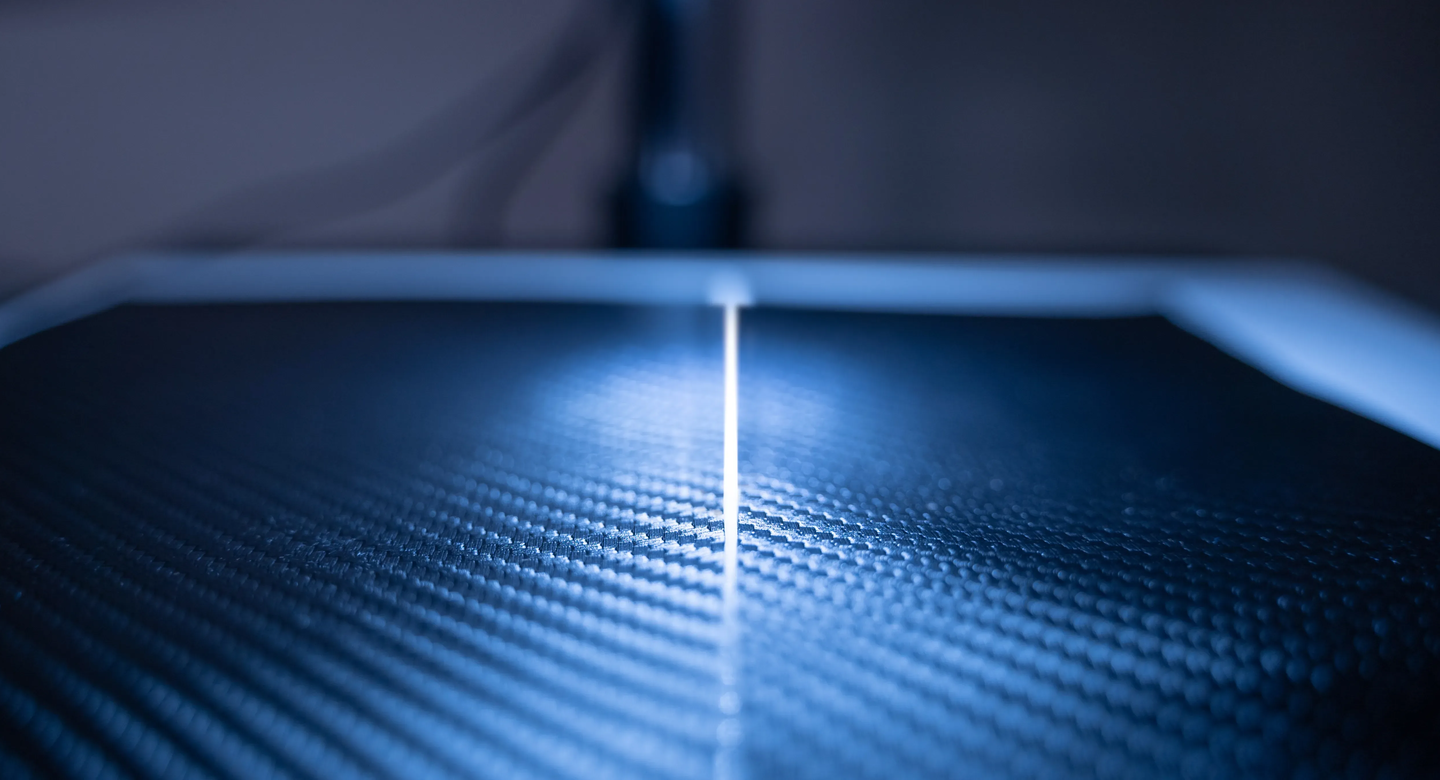

The quality of the cutting edge and the service life of the blades is highly dependent on the setting parameters to which each blade is adjusted. To achieve the best cut and the lowest burr, there is an optimum knife setting for each knife size and material type.

Optimum cutting quality can only be achieved with the right tools and systems, which we will recommend according to your application. Kaizen analysis provides an on-site, target/actual comparison of the relevant influencing factors.

Our Kaizen analysis offers the following services:

- Machine data

- Type of material being processed

- Cutting speed

- Material feed

- General condition of the cutting section

The DIENES Kaizen analysis identifies areas of opportunity by comprehensively recording all factors relevant to an optimal cutting result and presenting viable solutions. The comparison of target and actual values is carried out by our experienced experts, who know exactly what to pay attention to.

- Clear presentation of results

- Evaluation of the results

- Clear presentation of results.

- Evaluation of the results